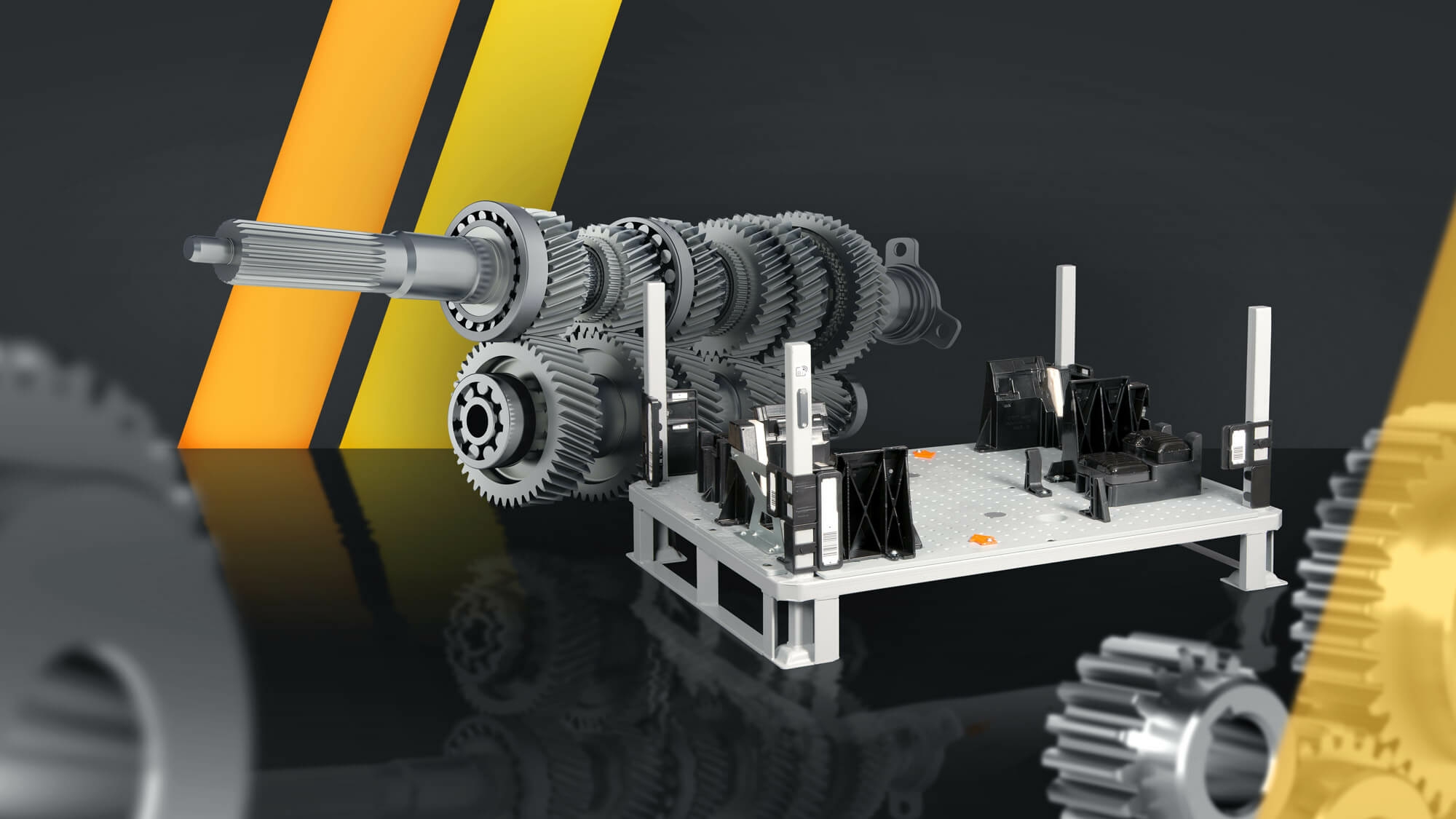

The GEBHARDT load carriers for Powertrain

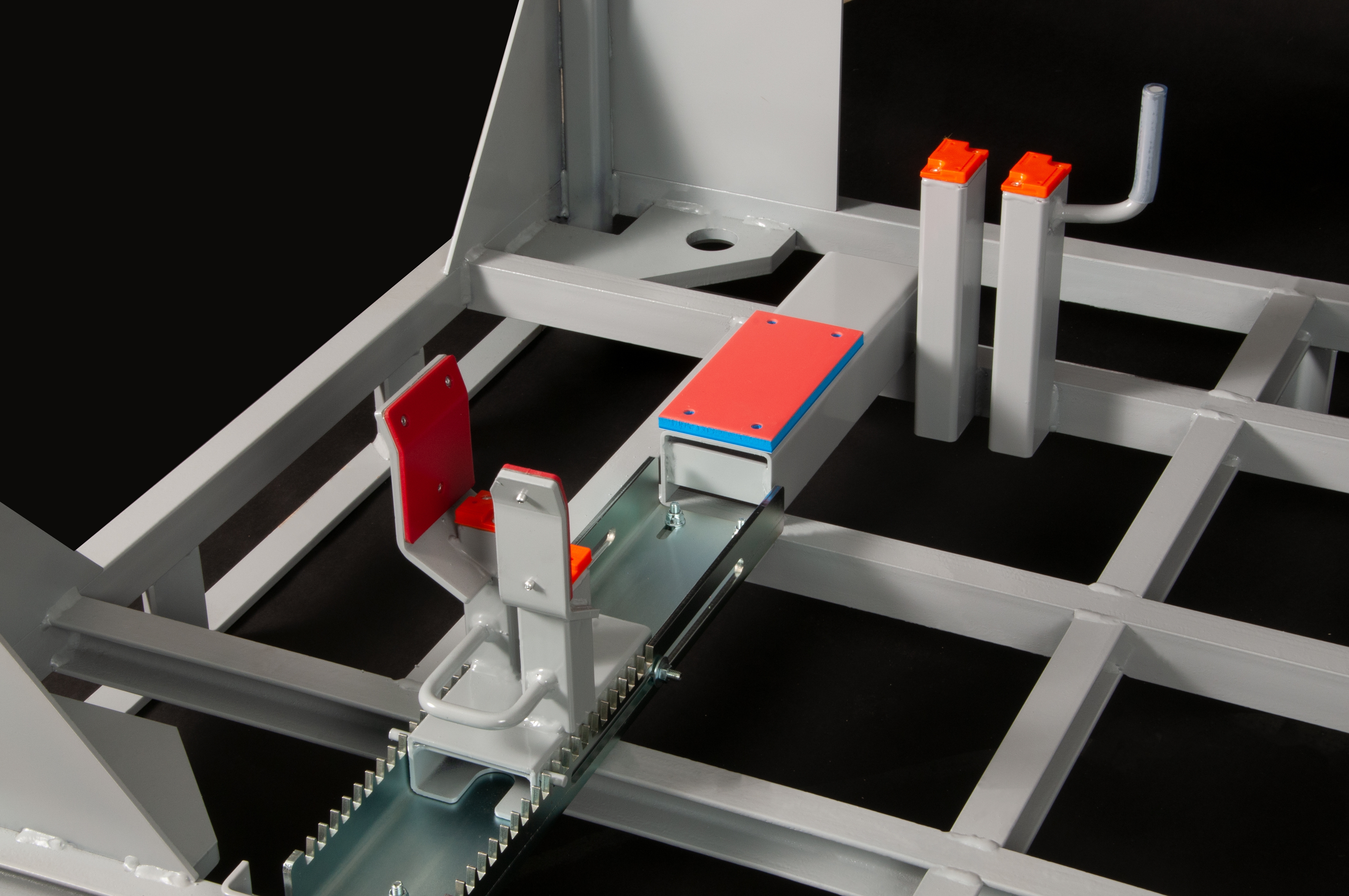

The transport and storage of highly sensitive products of the automotive industry such as engines, gearboxes or axles must meet the highest requirements for safety, precision and accuracy of fit. For this reason, there is no standard GEBHARDT special load carriers, but rather individual, tailor-made load carriers for the special requirements of our customers.

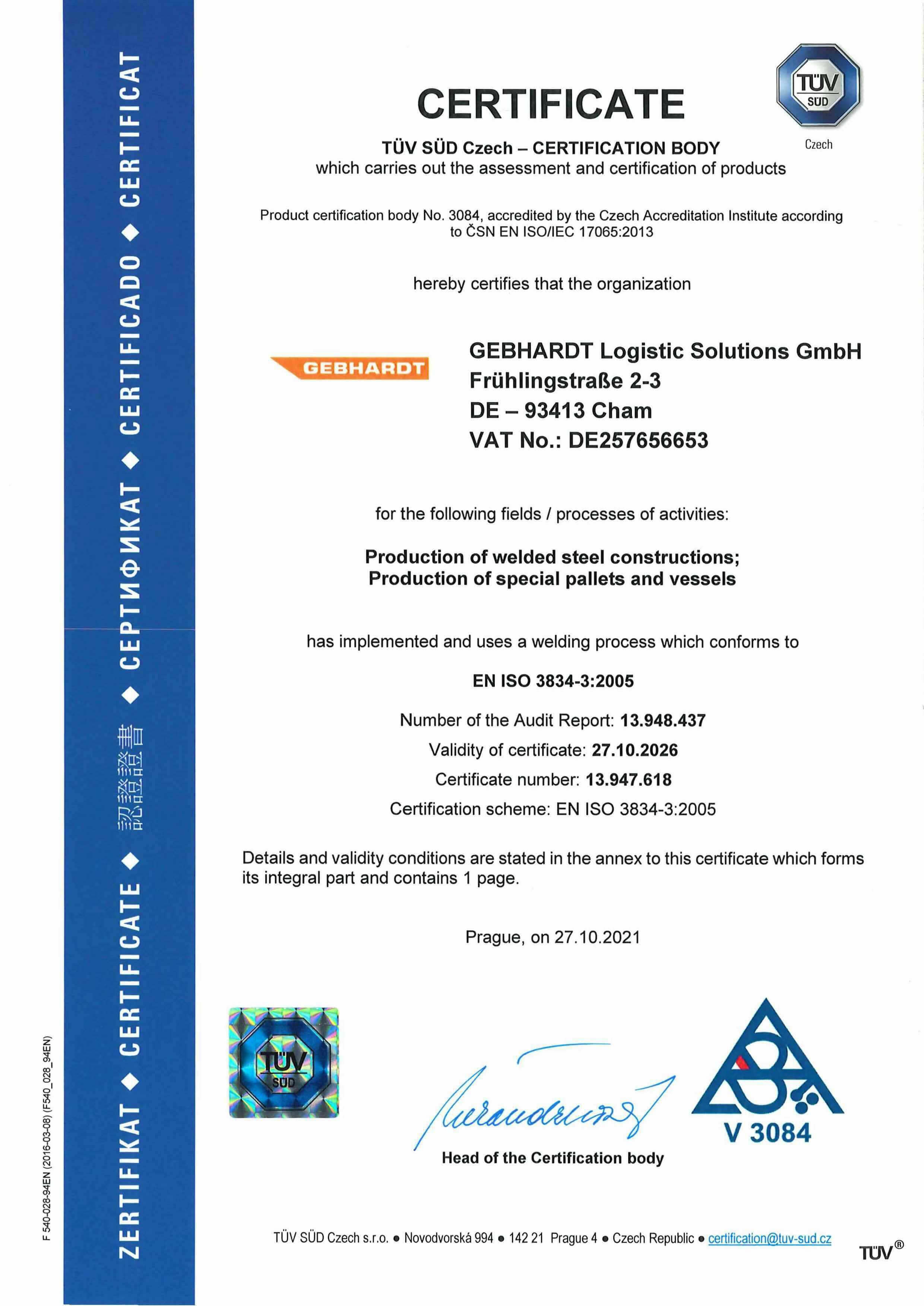

GEBHARDT has been developing and producing load carriers for national customers as well as international global corporations for over 195 years and convinces with automated production technology and the highest quality standards in series production. As the market leader in the industry, we have, thanks to our many years of experience, very extensive know-how as a manufacturer of transport racks and produce load carriers for automotive in always consistently high production quality.

GEBHARDT-Your specialist for transport and storage solutions in logistics!

Arrange a consultation appointment