The GEBHARDT load carriers for automated high-bay warehouses.

Sophisticated and process-safe load carriers. GEBHARDT load carriers are perfect for your automated processes.

Sophisticated and process-safe load carriers. GEBHARDT load carriers are perfect for your automated processes.

We drive the automation of logistics and offer you well thought out solutions to expand the storage possibilities in your automated high bay warehouse. The system pallets and platforms from GEBHARDT open up completely new possibilities far removed from previous standards. As a manufacturer of quality products, we ensure smooth processes through special dimensional accuracy, load-bearing capacity and deflection. Are you unsure about the eligibility of your products? We offer you a variety of tried and tested solutions. Learn more about GEBHARDT load carriers for automated high-bay warehouses and find the right special pallet for your application.

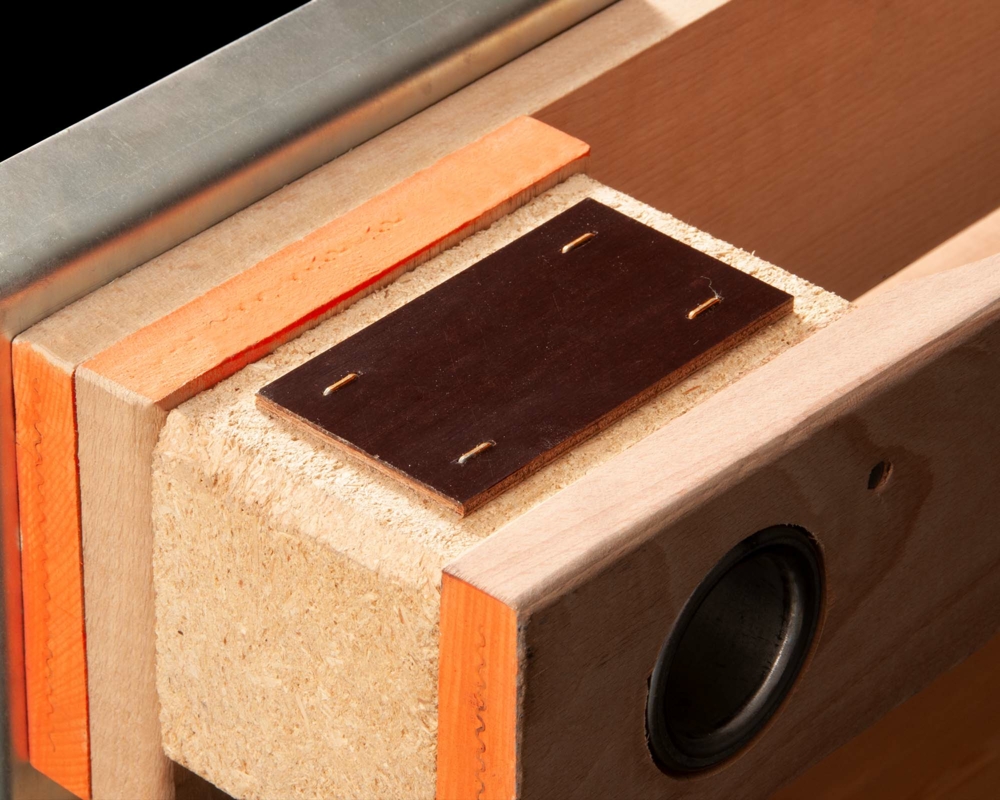

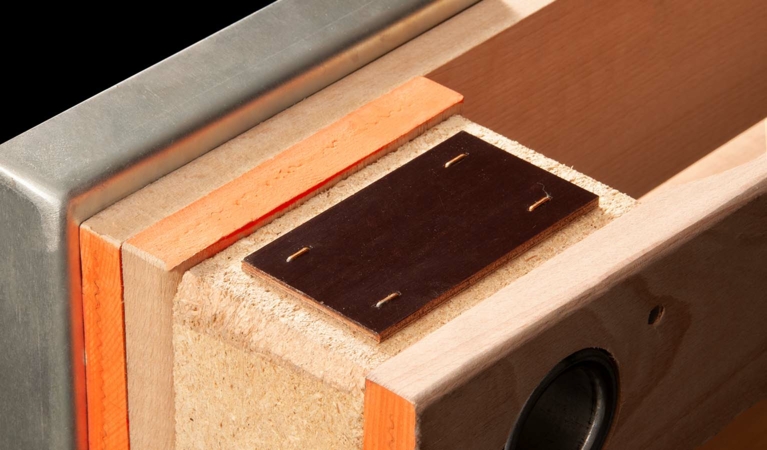

Do you have special requirements in terms of load and deflection in your warehouse? Depending on the load, the usual restrictions of 1,000 kg per storage space are quickly exhausted. Either the statics or the deflection becomes a problem. With our heavy-duty pallet, we solve this logistics problem, because the GEBHARDT load carriers are particularly load-bearing and specially adapted to your requirements. Through an intelligent combination of connection techniques such as rivets and the use of high-strength materials such as hardwood in combination with metal assemblies, we achieve the necessary stability of our special pallets. The products and requirements are tested and verified within our in-house test centre. The result is lean solutions with a long service life. Benefit from our years of experience and enquire about our individual system pallets without obligation!

Nobody needs disruptions in operation. We do everything to ensure that your automated processes run seamlessly and at high speeds and that downtimes are avoided. GEBHARDT system pallets and platforms are supplied with low-abrasion hardwood running surfaces to minimise contamination within the conveyor system. Our planed surfaces not only ensure less chipping, but also flat and even surfaces and contours. Drying and riveting ensure a high and sustainable dimensional stability of our four-way pallets. All in all, this results in almost trouble-free load carriers with a long shelf life. Within a short time, this results in economic advantages compared to other Euro pallets. Convince yourself of the advantages of our system pallets!

The know-how and experience from several decades of use within a wide variety of processes and circumstances is bundled within our configurator for pallets. Smart solutions for barcode labels and other preconceived solutions are fully integrated here. We would be happy to configure a logistics solution that is right for you. After requesting a handful of basic data, we will create an initial design for you within a very short time. Special themes and customer-specific designs are also possible at any time after consultation.

Inquire without obligation and use the diverse application possibilities of the GEBHARDT System Pallets® on the basis of configurable and proven standards!

We make your load transportable! Whether unsuitable one-way pallets or bulky goods with unsuitable contours, we will find a solution. With the GEBHARDT carrier pallets specially developed for your application, you can even integrate roller containers into automated systems without any problems. The robust and stable carrier pallets are designed for common conveyor techniques and storage and retrieval machines and can therefore be taken into account in your warehouse planning without any complications. Convince yourself of our well thought-out carrier pallets and benefit from more flexibility in your logistics processes!

Our products and projects focus on your logistics processes! Over 190 years of experience and know-how in our industry enable us to work with you to implement customised solutions and produce load carriers for conveyor technology. Benefit from the advantages of metal or hybrid solutions made of wood and metal. Our platforms are particularly suitable for large formats, bulky goods and heavy loads. The base frame can be modularly extended with compatible accessories such as stanchions or superstructures and optimally secure your load. Depending on the version, this can be magazined directly on the load carrier and does not require any additional space. Let our load carrier experts advise you and design your high-bay storage platform for conveyor technology that best supports your processes.

The optional equipment of our pallets with hollow rivets gives you more flexibility in your logistics processes. The pallet can either be used as a conventional system pallet or with tubular stirrups as a so-called tubular frame pallet. This system can be stacked several times and thus allows alternative uses. The tube frames can simply be inserted and removed in the hollow rivets of the pallet and can thus be converted quickly and without tools. In addition to stacking, they also offer the possibility to stabilise your load and thus also to bring it safely into the warehouse. We would be happy to show you the full range of possibilities and the associated advantages of the tubular frame pallet system in a personal consultation.

The GEBHARDT system pallets and trays are sustainable and pest-free load carriers.

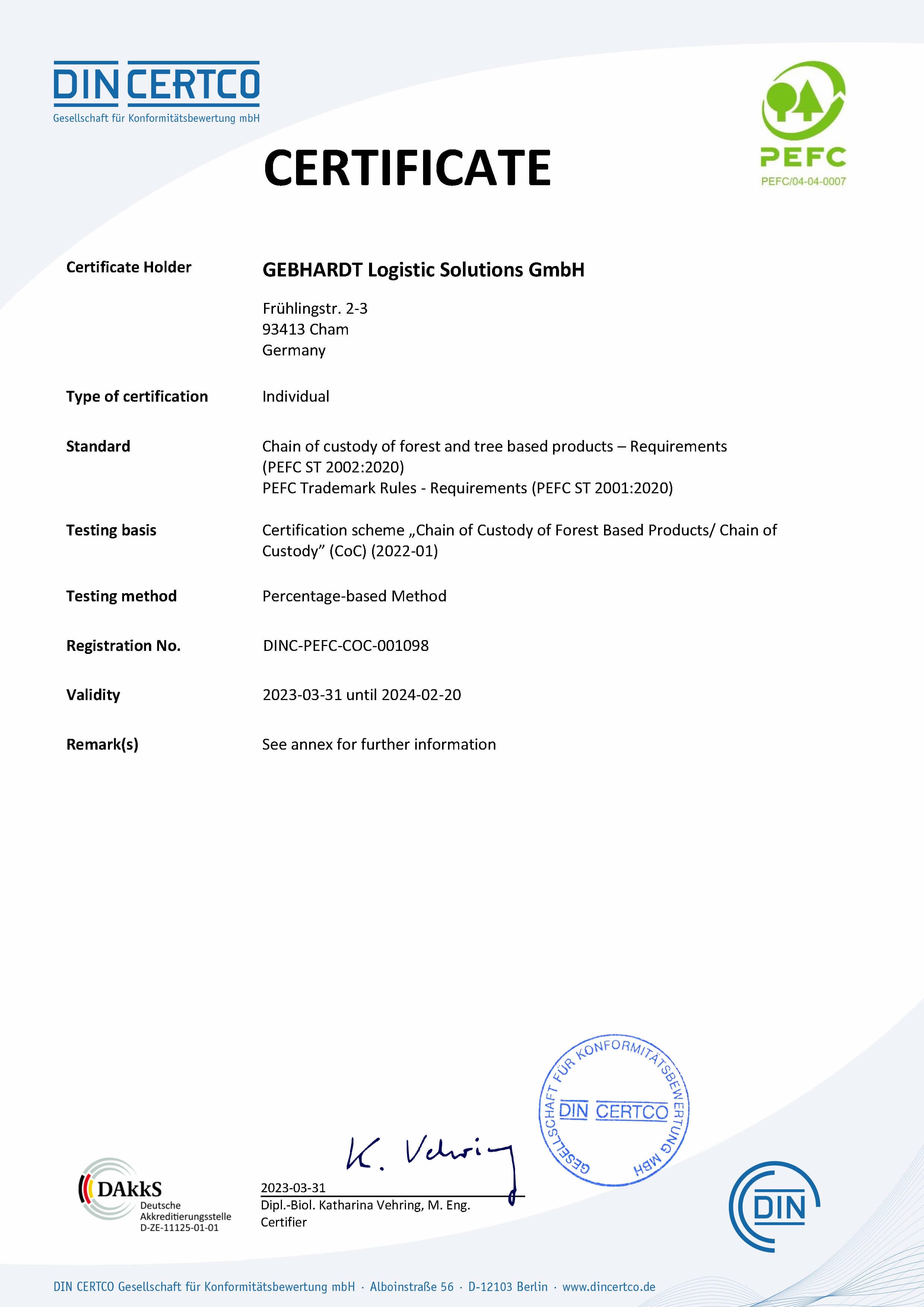

The PEFC certificate certifies that the wood used by GEBHARDT comes from a legal source and ensures sustainable forestry. Responsible and sustainable raw material procurement is important to us!

In our certified drying chambers we can heat treat your wood products in a controlled manner and efficiently remove possible pests.

Do you have any questions about GEBHARDT load carriers for automated high-bay warehouses or would you like individual advice? Please feel free to contact us!

The containers are monitored and tested several times during and after production by our in-house quality assurance department. In addition, GEBHARDT has the quality standard DIN ISO 9001 and we also carry out independent product monitoring.

Depending on the container design, different repair measures are possible.

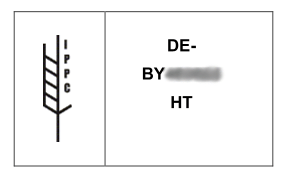

Depending on customer requirements, each wooden container can be treated IPPC or according to ISPM 15 in our in-house drying chambers on request.

GEBHARDT manufactures customised containers in addition to standard sizes. We would be happy to design an individual container for you. Please contact our sales team and arrange a free consultation!

GEBHARDT uses hardwood and softwood according to DIN EN 12246, Qual. Class P2. Please contact our sales team!

An attachment of customer-specific RFID tags and barcodes is possible and enables automated inventory management.